Products

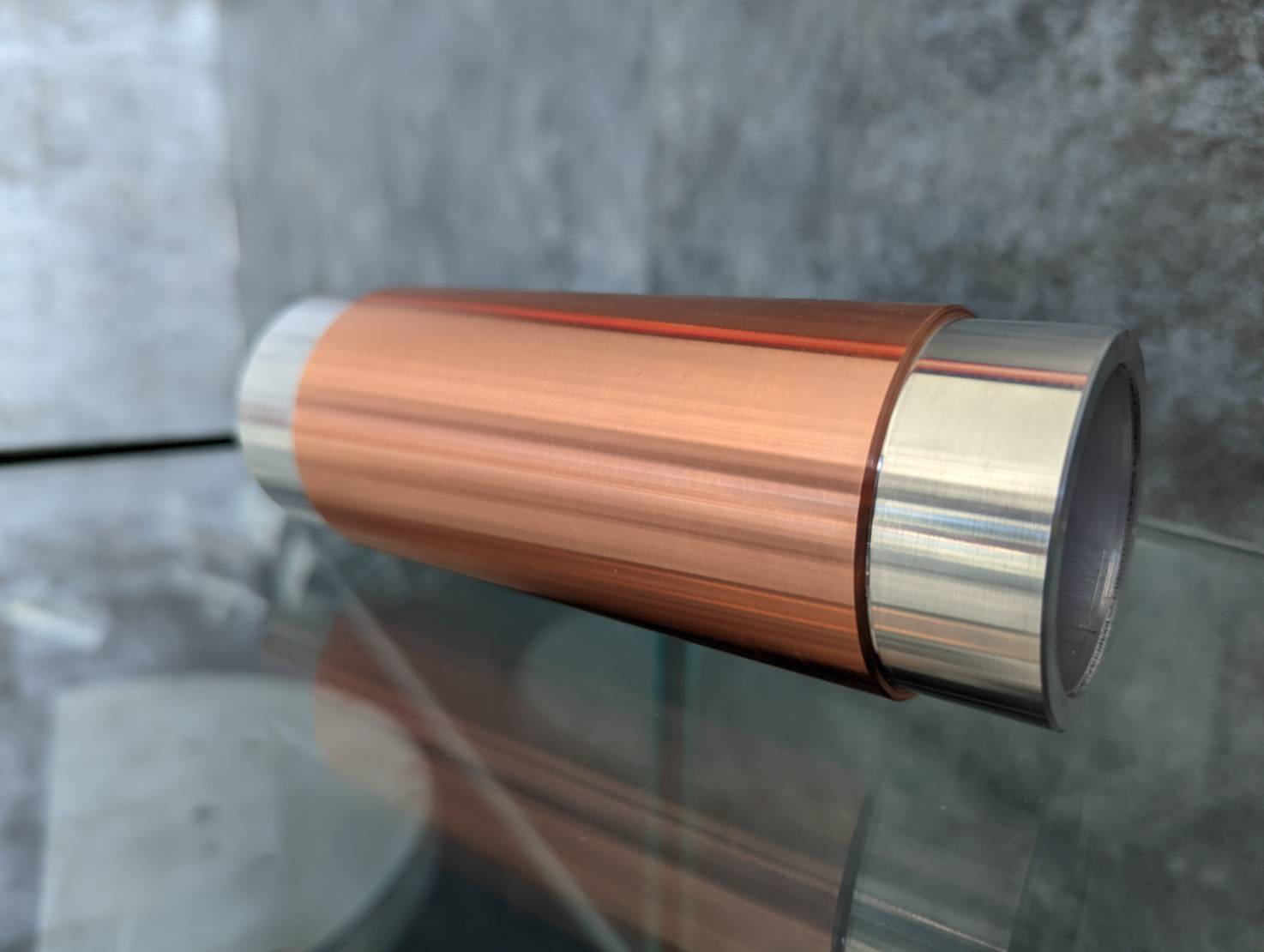

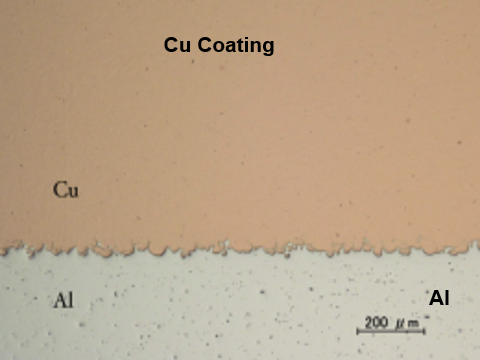

The cold spray process what PMT provide is a high pressure technology, impact the metal powder on the surface of the substrate at high speed by high-pressure inert gas. Metal particles are stacked into thick films during superplastic deformation. The difference with thermal spray is that the metal particles are not melted at high temperature in the high pressure cold spray process. That makes a denser, almost hole-free, oxide free, high purity metal film.

Kinetic energy of flying particle→Intensive plastic deformation of particle→Coating formation

Choice of layer material

Metal: Al, Cu, Ni, Ti, Ag

Alloy: Stainless steel, Aluminum alloy, nichromeLayer Properties

Thickness: 0.1mm~20mm or more

High density, high electrical conductivity, high thermal conductivity

Choice of substrate material

Metal, alloy, ceramics, high polymer

Process Properties

- ●Full solid‑state process

- ●Environmentally friendly

- ●High deposition rate

- ●Automatic production, stable quality